Energy From Waste Projects

Novalux have installed a variety of different renewable projects including Energy from Waste heat and power systems, commercial Solar PV, biomass boilers, Organic Rankine Cycle (ORC) and IED compliant biomass boilers.

To date, Novalux have installed over 110 projects for multinational companies and small businesses alike. The technology that Novalux installs benefit our customers’ businesses and finances, whilst helping the environment.

The example projects below demonstrates headline figures based on differing project requirements. If you’d like to get more accurate financial projections based on your site, submit the form below.

Project Scope

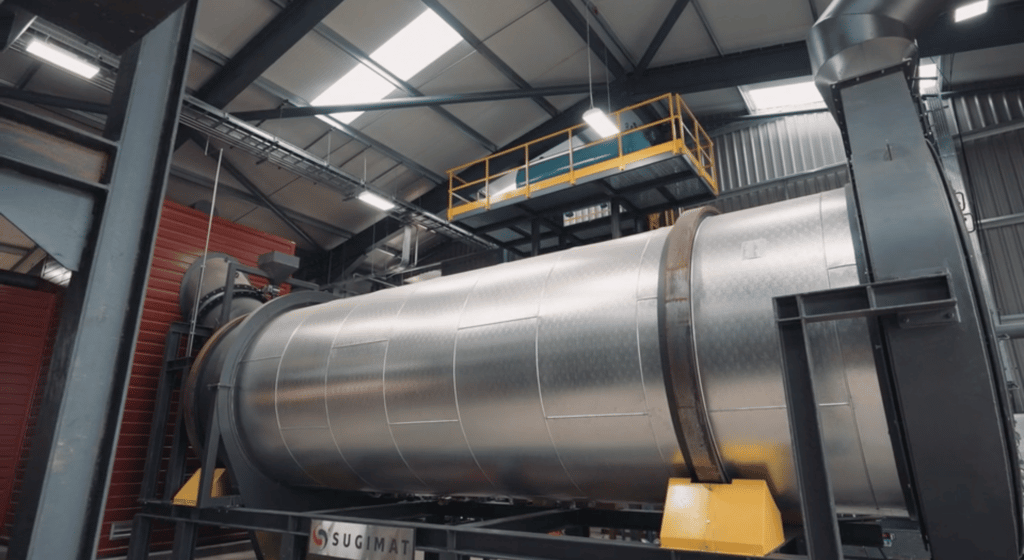

A large recycling site produces RDF from much of the waste they process. Novalux recommend that they diversify their business by installing a 14MWth Sugimat thermal oil boiler and 6.2MWe Turboden Organic Rankine Cycle (ORC).

The combined system will allow the recycling site to produce their own heat and power on site which they can use to cut down on costs or export to the grid under a PPA, creating a new income stream. Whilst saving an £85 gate fee, the business can also charge other companies for the disposal of their RDF, use waste as fuel and help contribute to a clean environment.

Project Financials

RDF Gate Fee: £3.9m

PPA: £1.3m

Payback 2.5 years

ROI: 40%

Project Scope

A large recycling business is looking to utilise the Municipal Solid Waste (MSW) which they send to landfill every day.

Novalux recommend that they install a 24MWth Sugimat thermal oil boiler and 6.5MWe Turboden Organic Rankine Cycle (ORC). The business owner can then use the MSW as fuel to generate heat and electricity which can be used on site or sold back to the grid through a power purchase agreement (PPA).

Project Financials

RDF Gate Fee: £4.5m

PPA: £2.3m

Payback: 3.6 years

ROI: 30%

Project Scope

A recycling business which deals with municipal solid waste needs to find a solution to the government restrictions placed on how much waste they are allowed to commit to landfill.

To solve this problem, Novalux suggests a 15MWth Sugimat thermal oil boiler with 3.3MWe Turboden Organic Rankine Cycle which is able to burn the waste as fuel, for space heating and turn excess heat into power to be used on site or sold back to the grid through a Power Purchase Agreement (PPA).

Installing the system also means the business no longer has to pay to dispose of the RDF, contributing to large long-term financial benefits.

Project Financials

Novalux provides solutions to help reduce your company’s carbon footprint whilst enjoying a large return on investment.

Figures below are per annum and based on an £85 gate fee.

RDF Gate Fee: £4.74m

PPA: £1.48m

Payback: 2.7 years

ROI: 40%

Project Scope

A business removing waste and sending it to landfill wanted to make savings on gate fees. Novalux suggested the installation of a 8MWth Sugimat thermal oil boiler, capable of burning plastics and waste without polluting the environment. Installing the system now will mean the business is prepared for the closures of landfill sites.

Novalux also recommends a 2MWe Turboden Organic Rankine Cycle (ORC) which generates power from excess heat produced by the boiler, by installing this the business can also make savings on electricity costs whilst earning income from selling excess electricity back to the grid through a Power Purchase Agreement (PPA).

Project Financials

All of the systems which Novalux installs have large financial benefits for our customers whilst reducing carbon outputs. The figures below are based on a £100 gate fee being charged for the removal of RDF.

RDF Gate Fee: £1.85m

PPA: £771,200

Payback 3.2 years

ROI: 30%

Project Scope

A skip company which has to dispose of RDF by paying for it to go to landfill or to be used in a large ERF facility, can choose to install their own thermal oil boiler. By doing this, they can save an £80 gate fee.

In addition to this saving, Novalux suggests combining the 5.5MWth Sugimat boiler with an 1.3MWe Turboden Organic Rankine Cycle (ORC) so that the site can efficiently turn heat from the boiler into power for use on site or export it to the grid under a Power Purchase Agreement (PPA). By investing in their own system the recycling site are able to provide their business with a long term income stream whilst helping to keep the environment clean.

Project Financials

Choosing to opt out of the traditional energy model can provide large financial benefits for your business.

Every system Novalux installs provides long term solutions to the rising price of electricity and gas, whilst helping the environment. The figures below are per annum and based off a £80 gate fee to accept RDF.

RDF Gate Fee: £1.23m

PPA: £400,000

Payback: 3.5 years

ROI: 30%

Questions?

Whether you’d like to book a site survey or you’re unsure about which technology is right for your business, our team can help.